Leka's orangery roof conversion kit replaces your existing fibreglass, traditional build, glass or polycarbonate roofing system with a lightweight, tiled, Orangery roof replacement system.

It is a truly lightweight, tiled. Orangery roofing system finished with replica concrete (Metrotile) or slate (TapcoSlate) tiles. These engineered tiles weigh up to seven times less than the real thing and are a perfect imitation.

The orangery kit is designed for homeowners and built for the trade. It’s incredibly lightweight, easy to install and complies with building regulation U-values. There are no aluminium or timber components in the build. The Leka System is built from four simple ladder kits made from GRP (glass reinforced plastic).

If you’re looking to upgrade, replace or convert an orangery roof, our orangery roof conversion kit is up to 40% lighter than competitor products. It’s the cutting-edge roofing system of choice for many installation companies and homeowners because of this. When only the very best will do, the Leka System delivers.

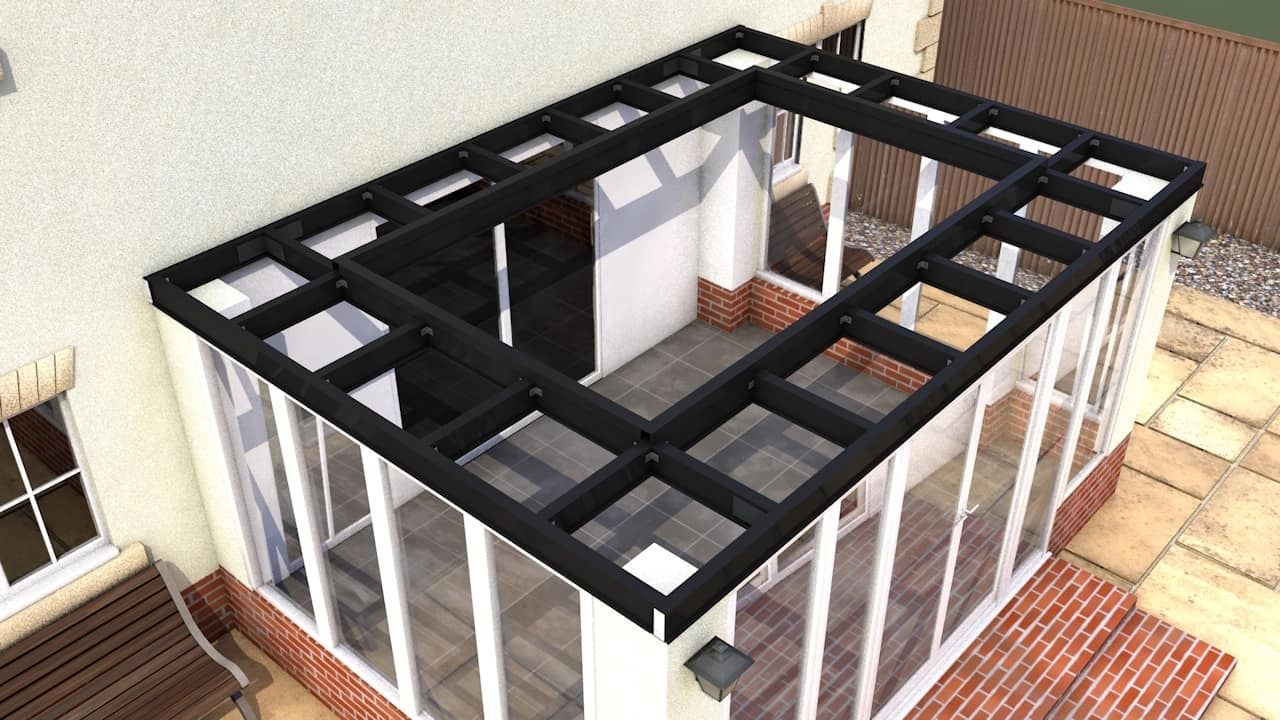

Step 1 - GRP Rafters

First, 'Glass Reinforced Plastic' rafters are added to your existing, Orangery window frames, including a GRP structural ring beam, rafters and ridge. GRP is not prone to:

- wood worm

- moisture absorption such as traditional timber

- condensation

- thermal bridging such as bulky Aluminium alternatives.

- The beginning of your improved Orangery roof insulation.

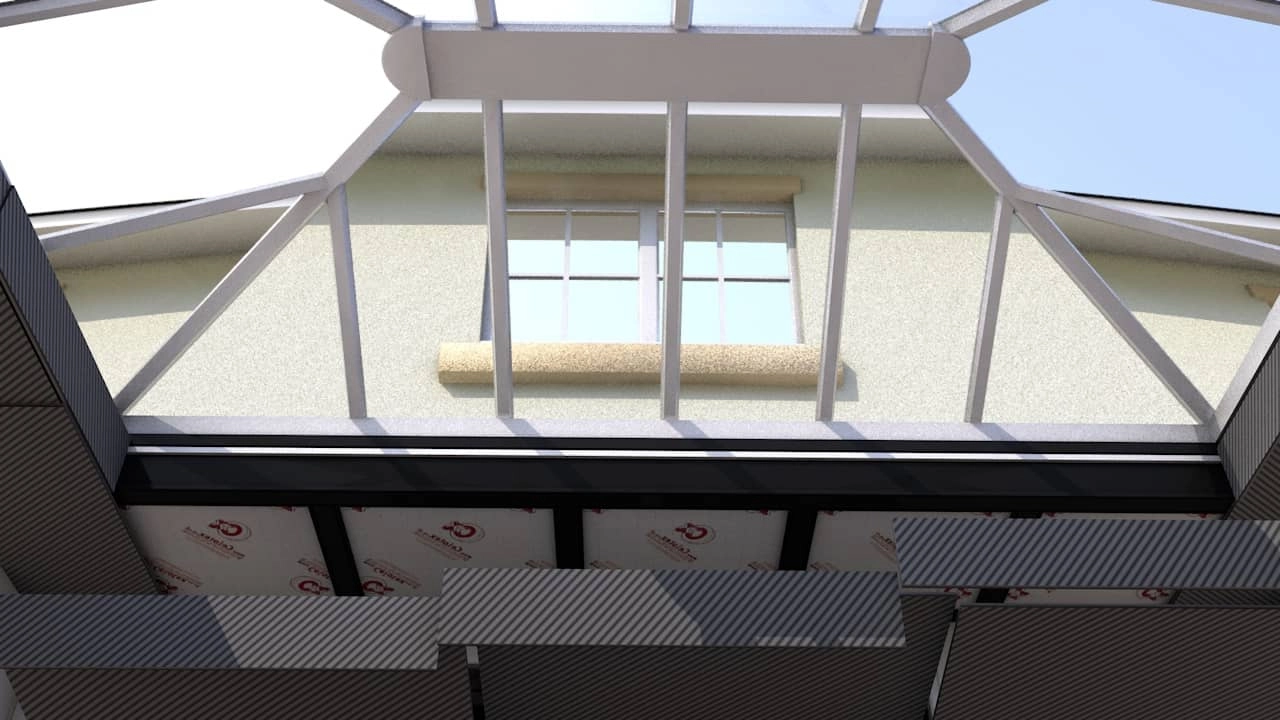

Step 2 - Celotex Insulation

Insulated Celotex sheets are snugly fitted with a 15mm gap from the internal Leka sheets. Celotex is one of the UK's leading insulation specialists, providing high-value thermal efficiency and BBA certified and a significant benefit in achieving a better Orangery, roof insulation efficiency level.

Step 3 - Outer Sheets

Next, strong, load-bearing and insulated outer sheets are added. These ensure less roofing bars and higher efficiency.

Leka outer boards have been engineered to offer:

- A structural alternative to plywood

- A significantly lighter alternative to any other roof covering board

- A 100% waterproof outer covering

- A thermally efficient board

Step 4 - Outer Weatherproof Coating

An outer weatherproof coating is then applied by your installation company.

This will provide final waterproofing along with a stylish finish, ensuring that your Orangery roof is the ultimate in watertight insulation.

Step 5 - Glass Lantern

The glass lantern will allow light to flood through into the Orangery and provide an elegant looking finish.

Step 6 - Fascias and Guttering

UPVC fascias and cappit are now attached onto the edges of the structure.

This then allows guttering to also be attached onto the UPVC fascias cappit as an optional step.

Step 7 - Internal Leka Boards

Next, internal Leka sheets are added underneath the GRP rafters. The Leka sheets are 100% waterproof and one third the weight of plasterboard.

These sheets have unique thermal qualities as well, but allow for a traditional plaster skim finish to provide a nice visual aspect ready for painting afterwards. For a more traditional cost effective finish, standard 12.5mm plasterboards can also be utilised as part of the Leka ECO range which (in most cases) doesn’t affect our exceptional U values of 0.15.

Step 8 - Internal Plaster

The underside of the roof then has a high quality, traditional skim plaster finish applied.

Low energy spotlights can then also be fitted for the best possible interior lighting.